Location Planning

Every firm must use location planning techniques.

There are many options for location planning. Corporations choose from

expanding an existing location, shutting down one location and moving to

another, adding new locations while retaining existing facilities, or doing

nothing. There are a variety of methods used to decide the best location or

alternatives for the corporation. Methods such as identifying the country, general

region.

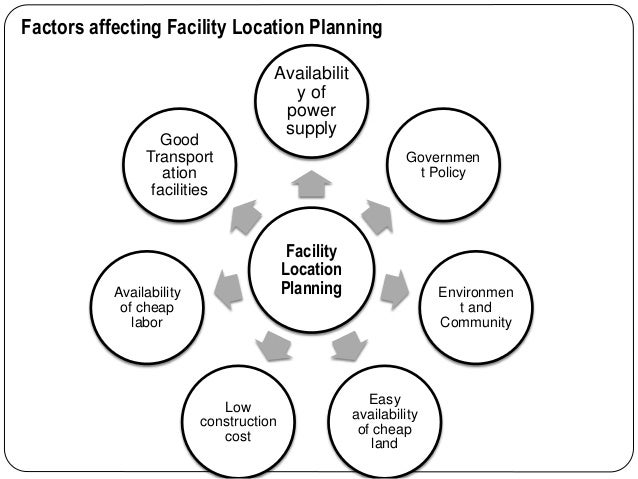

Several factors that influence location positioning include the location of raw materials, proximity to the market, climate, and culture. Models for evaluating whether a location is best for an organization consist of cost-profit analysis for locations, the centre of gravity model, the transportation model, and factor rating.

Several factors that influence location positioning include the location of raw materials, proximity to the market, climate, and culture. Models for evaluating whether a location is best for an organization consist of cost-profit analysis for locations, the centre of gravity model, the transportation model, and factor rating.

The main factors that affect location decisions

include regional factors, community considerations, and site-related factors.

Community factors consist of quality of life, services, attitudes, taxes,

environmental regulations, utilities, and development support.

IDENTIFYING REGION- 4 major considerations

·

Location to Raw

Materials: The three most important reasons for a

firm to locate in a particular region include raw

materials, perishability, and transportation cost. This often depends on what business the

firm is in.

·

Location to Markets: Profit

maximizing firms locate near markets that they want to serve as part of their

competitive strategy. A Geographic

information system (GIS) is

a computer based tools for collecting, storing, retrieving, and displaying

demographic data on maps.

·

Labour Factors: Primary considerations include labour

availability, wage rates, productivity, attitudes towards work, and the impact

unions may have.

·

Other: Climate is sometimes a consideration because bad weather can

disrupt operations. Taxes are also an important factor due to the fact that

taxes affect the bottom line in some financial statements.

IDENTIFYING

A SITE

The main considerations in choosing a site are

land, transportation, zoning and many others. When identifying a site it is

important to consider to see if the company plans on growing at this location.

If so, the firm must consider whether or not location is suitable for

expansion. There are many

decisions that go into choosing exactly where a firm will establish its

operations. First, a company must determine the driving factors that will

influence which areas are suitable locations. After these factors have been

determined, the company will identify potential countries and examine the pros

and cons of establishing operations in these countries. After looking at pro

and cons of the different countries and deciding on a country, then decision

makers will identify a region within the country. When identifying a region,

decision makers must take the four major factors explained above into

consideration. The last two stages of the search include choosing a community

and a site.

Method

used for calculating the location of the Distribution Centre and the regional

warehouses-

Centre of Gravity Method:

This technique is used in determining

the location of a facility which will either reduce travel time or lower

shipping costs. Distribution cost is seen as a linear function of the distance

and quantity shipped. The Centre of Gravity Method involves the use of a visual

map and a coordinate system; the coordinate points being treated as the set of

numerical values when calculating averages. If the quantities shipped to each

location are equal, the centre

of gravity is found by taking the averages of the x and y coordinates;

if the quantities shipped to each location are different , a weighted average must be applied (the weights

being the quantities shipped)

Calculation:

1.

Calculation of No of items in shipment:

The semi-trailers can hold up to 33

pallets

Each pallet can hold how many cartons:

One Pallets dimension =800 x 1200 Cm

One carton will be occupying an area

of =60 x 40 Cm

Therefore, the no: of cartons loaded

(as in first layer) =800 x 1200/(60 x

40) =400 Cartons

No: of layers (wrt height) = 240/30= 8

layers

No: of cartons in

semitrailers(shipped)= 400 x 8 x 33 = 105600 Cartons

There are 4 warehouses for 4

respective factories

so

the actual cartons shipped = 4 x 105600=422400 Cartons

2.

Items in Circulation:

No

of items in circulation= regional + shipped

There

are 4 regional warehouse for each factory, so the no: of items in circulation

for each factory =4 x 500=20000

For

4 factories =20000 x 4= 80000

.:

the total items in circulation = 422400+80000=502400

Assumptions:

1. The Demands for one particular date 01-2019

04-is considered.

2. The demands of all the customers are met.

3. The regional warehouses are located near the

place where there is more demand

4. If the city with more demand is met, then the

demand in the surrounding places can be met accordingly.

5. The values applied on demand are approximated

to some degree.

Lorsch

Each

central warehouse need to meet 82678 items/month.

Buttenheim: 1794/500= 4 trucks

Hamburg: 1776/500= 4 trucks

Berlin: 1608/500= 4 trucks

Köln: 1191/500= 3 trucks

Mannheim

Each

central warehouse need to meet 172159 items/month.

Mönchengladbach: 5823/500= 12 trucks

Lüdwigshafen: 1447/500= 3 trucks

Braunswick: 1456/500= 3 trucks

Berlin:

1696= 4 trucks

Vechta

Each

central warehouse need to meet 63154 items/month.

Köln: 1395/500= 3 trucks

Hamburg: 1382= 3 trucks

Frankfurt am Main: 483= 1 truck

Dresden= 143/500= 1 Truck

Mönchengladbach

Each

central warehouse need to meet 276286 items/month.

Köln: 13912/500= 28 trucks

München: 3475/500= 7 trucks

Berlin: 3524/ 500= 8 trucks

Hamburg:

5409/500= 11 trucks

S.No

|

Central Warehouse

|

Regional Warehouse

|

Percentage demand/

regional Warehouse

|

Trucks needed per

Regional warehouse

|

1

|

Lorsch

|

Büttenheim

|

49.2

|

4

|

Berlin

|

27.8

|

4

|

||

Hamburg

|

25.2

|

4

|

||

Köln

|

18.7

|

3

|

||

2

|

Mannheim

|

Mönchengladbach

|

55.8

|

12

|

Lüdwigshafen

|

13.8

|

3

|

||

Brunswick

|

13.9

|

3

|

||

Berlin

|

16.2

|

4

|

||

3

|

Vechta

|

Köln

|

48.8

|

3

|

Hamburg

|

43.3

|

3

|

||

Frankfurt am

Main

|

15.1

|

1

|

||

Dresden

|

4.4

|

1

|

||

4

|

Mönchengladbach

|

Köln

|

52.8

|

28

|

München

|

13.2

|

7

|

||

Berlin

|

13.3

|

8

|

||

Hamburg

|

20.5

|

11

|

The no: of items in circulation:

The No. of items in circulation for a

single day (04-01-2019) is calculated,

S.No

|

Central Warehouse

|

Demand on the selected day

|

1

|

Lorsch

|

1200

|

2

|

Mannheim

|

7181

|

3

|

Vechta

|

4500

|

4

|

Mönchengladbach

|

13431

|

Locations:

The location of the customers,

location of the factory, location of the central warehouse and location of the

regional warehouses are calculated according the given Longitudinal and

Latitudinal positions and they are marked in Google maps for better

understanding and reference.

Locations of the Factories:

S. No

|

Representation of the factories

|

Latitudinal value

|

Longitudinal Value

|

1

|

Mannheim

|

49.494034128078000

|

8.45711420315853

|

2

|

Lorsch

|

49.6409044696465000

|

8.56493556447512

|

3

|

Mönchengladbach

|

51.1963658241177000

|

6.43379455120694

|

4

|

Vechta

|

52.7428116120401000

|

8.2836006861168300

|

Location of the Central Warehouses:

Sample Calculation for Central Warehouse

location for Lorsch:

Total Sum of Demand = 82678

∑ Lat X Demand = 4207211.115

∑ Long X Demand = 782148.4652

Lat for Central Warehouse (x)

=782148.4652/82678 = 9.46017641

Long for Central Warehouse (y) =

4207211.115/82678= 50.8867064

S. No

|

Representation of the

Central warehouses

|

Latitudinal value

|

Longitudinal Value

|

1

|

Mannheim

|

50.16541035

|

7.742670888

|

2

|

Lorsch

|

50.8867643

|

9,46017641

|

3

|

Vechta

|

50.07490742

|

7.924501258

|

4

|

Mönchengladbach

|

51.0761371,

|

7.981192811

|

Location of the regional warehouses:

Lorsch

S.No

|

Representation of the Regional

Warehouses

|

Latitudinal value

|

Longitudinal Value

|

1

|

Buttenheim

|

49.82950824

|

11.07254563

|

2

|

Berlin

|

52.5729887447053000

|

13.443301207034300

|

3

|

Hamburg

|

53.5878682327500

|

9.734921306135

|

4

|

Köln

|

50.92480502

|

6.950127682

|

Vechta:

S.No

|

Representation of the Regional

Warehouses

|

Latitudinal value

|

Longitudinal Value

|

1

|

Frankfurt am main

|

50.0238419217

|

8.84232127

|

2

|

Dresden

|

51.009786542

|

13.31715272

|

3

|

Hamburg

|

53.572472791

|

10.151723147

|

4

|

Köln

|

50.8724347619

|

6.8714321719

|

Mannheim:

S. No.

|

Representation of Regional

Warehouse

|

Latitude

|

Longitude

|

1.

|

Mönchengladbach

|

51.203457971

|

6.741327154

|

2.

|

Lüdwigshafen

|

49.497254721

|

|

3.

|

Braunschweig

|

52.2864327

|

10.433217900

|

4.

|

Berlin

|

52.427134171

|

13.541297524

|

Mönchengladbach:

S. No.

|

Representation of Regional

Warehouse

|

Latitude

|

Longitude

|

1.

|

Köln

|

50.8724347619

|

6.8714321719

|

2.

|

Hamburg

|

53.572472791

|

10.151723147

|

3.

|

Frankfurt

|

50.0238419217

|

8.81232127

|

4.

|

Dresden

|

51.009786542

|

13.31715272

|

Comments

Post a Comment